|

| October 27, 2015 | Volume 11 Issue 40 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

New inductive temperature sensing reaches places other techniques can't

The technique applies the eddy current principle to high-temp measuring applications from steel processing to home cooking.

The Technology Partnership (TTP), one of Europe's leading technology and product development companies, has come up with an innovative new non-contact way to measure high temperatures for applications ranging from foundries, machining and food processing, to use on aircraft engines and braking systems -- and even for low-cost applications in the home. The new patent-pending inductive technique has already been used over temperature ranges of several hundred degrees Celsius with an accuracy of 1 deg C and could replace existing contact methods such as thermocouples and the use of infrared.

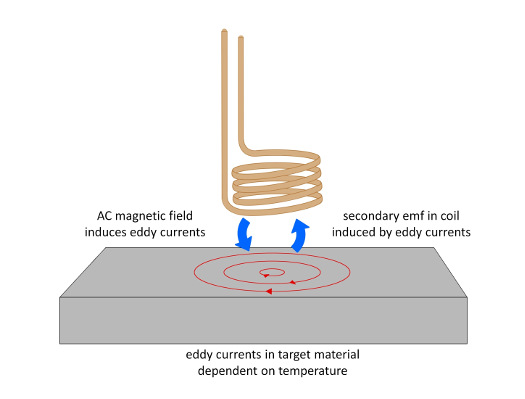

Researchers at TTP (located near Cambridge, UK) used the well-known principle that applying an alternating current to a coil will induce eddy currents in nearby metallic objects -- an effect commonly used in proximity sensors and non-destructive testing -- looking for cracks or voids in material, for example. But TTP has exploited the fact that the flow of eddy currents is also dependent on the material's temperature and can be used to provide a completely new approach to non-contact temperature sensing.

Using a special coil arrangement, sensing methodology, and algorithm to detect and measure the induced eddy currents, TTP researchers have been able to implement inductive temperature sensing of targets in a wide range of challenging environments, through metal barriers, and even in applications where the geometry of the target material is unknown.

"Inductive temperature sensing is ideal for applications where contact methods are not reliable and where lack of line-of-sight access, variable emissivity, or high cost limit the use of infrared techniques," says Dr. David Pooley, senior consultant at TTP. "And because of the simplicity of applying the technology in practical environments, it could also be used in low-cost consumer applications."

Eddy currents were first discovered by French physicist Leon Foucault in 1851, following the discovery of electromagnetic induction by Michael Faraday in 1831. But it was not until the 1930s that eddy-current technology started to be used for industrial applications.

"It's very exciting to take a 165-year-old principle and discover a completely new range of applications for it," says Pooley. "We are continuing our practical trials to refine the process and explore new applications, and we are already getting a lot of interest from potential partners to commercialize the technology and take it to market."

Source: TPP

Published October 2015

Rate this article

View our terms of use and privacy policy